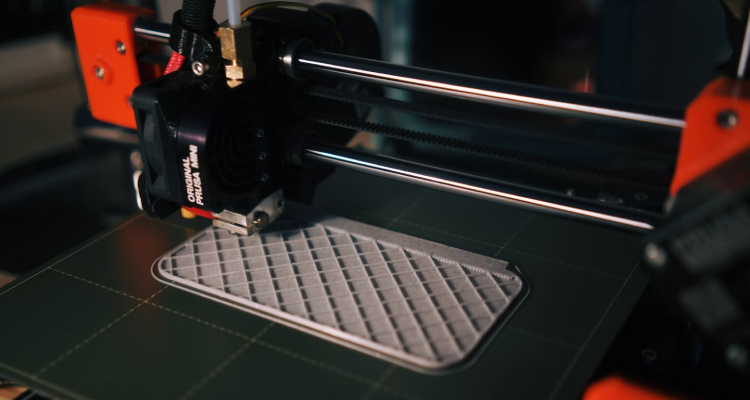

The aviation industry has always been at the forefront of technological innovation. In recent years, one technology that has caught the attention of aerospace engineers and manufacturers alike is 3D printing. Also known as additive manufacturing, this technology holds the promise to revolutionize aircraft manufacturing. This article delves into the various ways 3D printing is shaping the future of aviation, from design to production and even maintenance.

Why 3D Printing in Aviation?

- Cost-Effectiveness: Traditional manufacturing methods often require expensive molds and extensive labor. 3D printing slashes those costs.

- Speed: The speed of prototyping and production can be significantly increased.

- Complexity and Customization: 3D printing allows for the creation of complex geometries that are difficult or even impossible to manufacture using traditional methods.

Key Applications in Aircraft Manufacturing

Prototyping

Rapid prototyping is perhaps the most straightforward application. Engineers can quickly produce and tweak designs, accelerating the development process.

Component Manufacturing

Certain aircraft components can be directly manufactured using 3D printing technologies, reducing weight and improving efficiency.

Tooling

3D printing can also be used to manufacture specialized tools required during the aircraft assembly process.

Real-World Examples

- GE Aviation: Their LEAP engine features 3D-printed fuel nozzles that are lighter and more durable.

- Airbus: Utilizes 3D-printed components in its A350 XWB model, resulting in weight reduction.

- Boeing: Employs additive manufacturing in producing over 50,000 3D-printed parts across its fleet.

Challenges and Considerations

While 3D printing offers many advantages, there are also challenges such as quality control, material limitations, and regulatory hurdles that need to be addressed.

Frequently Asked Questions

How is 3D printing used in aircraft manufacturing?

3D printing in aviation is used for rapid prototyping, direct component manufacturing, and tooling.

What are some real-world examples of 3D printing in aviation?

GE Aviation’s LEAP engine, Airbus's A350 XWB, and Boeing's extensive use of 3D-printed parts are prime examples.

What are the challenges facing the adoption of 3D printing in aviation?

Quality control, material limitations, and regulatory hurdles are some of the challenges that need to be addressed for wider adoption.

Conclusion

The potential of 3D printing in aircraft manufacturing is undeniable. It offers advantages in speed, cost, and design complexity that traditional methods can't match. As technology advances and overcomes current challenges, 3D printing is set to become increasingly integral to the aviation industry.